One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

The medium frequency pipe bending machine adopts medium frequency induction heating technology to locally heat the pipe to be bent to a plastic state, and then bends it into the desired shape through mechanical force. Specifically, the induction coil in the equipment generates medium frequency current, which generates eddy current on the surface of the pipe, thereby rapidly heating the pipe. At the same time, the bending die of the pipe bending machine bends the heated pipe.

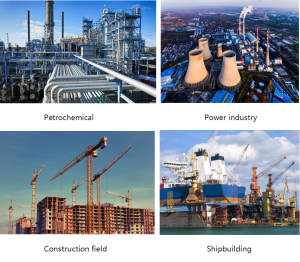

Mainly used for bending large metal pipes, including the following fields:

1.Petrochemical: used to manufacture oil pipelines, chemical pipelines, etc.

2.Power industry: used to make power station boiler pipelines, nuclear power plant pipelines, etc.

3.Construction field: can be used to make bent pipe components in building structures.

4.Shipbuilding: used to manufacture ship piping systems.

Recently, ANTISHICNC received an inquiry from a thermal power plant. The customer wants to manufacture bent pipes for steam pipes and water supply pipes in thermal power plants. The maximum diameter of the pipe can reach 426 mm, the wall thickness can reach 55 mm, and the maximum length is 12m. Bending angle 90 degrees, outer diameter bending radius not less than 2.0 x О.D., ovality of the cross section of the bent pipe – not more than 8%.

According to customer needs, we recommended the following model ZPW-4264-50

| Specifications | Parameters | unit | Remarks | |

| Pipe diameter | 76-426 | mm | ||

| Max pipe wall thickness | 55 | mm | ||

| R Bending Radius R | Adjust range of machine body | 2D-2700mm | mm | |

| Relative bending radius | ≥2.0D | mm | ||

| One time bending angle | 0~90° | Degree | ||

| Bending angle accuracy | ±0.5 | Degree | ||

| Ovality | <2.5%~8% | – | ||

| Min length of the front straight pipe part | ≤500 | mm | ||

| Min length of the back straight pipe part | ≤2500 | mm | ||

| Max loading pipe length | 12000 | mm | ||

| medium frequency device | Power | 350 | KW | |

| Frequency | 500~1000 | HZ | ||

| Main Oil cylinder pushing force in theory | 120 | ton | ||

| Main Oil cylinder run distance | 8000 | mm | ||

| Hydraulic system work pressure | 21 | Mpa | ||

| Bending speed adjust range | 0.05~1.1 | mm/s | Step-less speed regulation | |

| Allowable deviation of speed during bending | ±2.5 | mm/min | Allowable deviation of speed during bending | |

| Quick advance speed of rear chuck | ≥1.5 | m/min | Quick advance speed of rear chuck | |

| Quick return speed of rear chuck | ≥1.5 | m/min | Quick return speed of rear chuck | |

If you have similar pipe bending needs, please contact ANTISHICNC.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.