One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

1. Application Scenarios of Stainless Steel Pipes

2. Processing Applications of Automatic Pipe Bending Machines

3. Classification of Automatic Pipe Bending Machines

4. Principle of Automatic Pipe Bending Machines

5. Cold Bending and Hot Bending Methods of Pipe Bending Machines

6. Requirements for Pipe Bending Machines for Complex Processes

Stainless steel pipes are widely used in various industries, including automotive fuel systems, heat exchangers, air conditioners, refrigerators, and aerospace. Automatic pipe bending machines are mechanical devices used to bend steel pipes in power construction, boilers, bridges, ships, furniture, and decoration. They can be broadly categorized into manual pipe bending machines, CNC pipe bending machines, and hydraulic pipe bending machines.

1. Application Scenarios of Stainless Steel Pipes

Stainless steel pipes have a wide range of applications in daily life, appearing in many key industries. For example, in automotive fuel systems, they are crucial channels for transporting fuel and lubricating oil, ensuring stable operation; in heat exchangers, they serve as heat exchange elements, efficiently transferring heat thanks to their excellent thermal conductivity and corrosion resistance; in air conditioning and refrigeration systems, stainless steel pipes are responsible for refrigerant transport, ensuring cooling performance; even in the aerospace field, where material requirements are extremely high, stainless steel pipes are used to manufacture various piping components, supporting the normal operation of equipment. The production and operation of these industries are inseparable from stainless steel pipes.

2. Processing Applications of Automatic Pipe Bending Machines

Automatic pipe bending machines, as specialized machinery for bending steel pipes, also have diverse applications. They are used for bending steel pipes for building power supports in power construction, bending boiler body piping during boiler manufacturing, shaping steel pipes for bridge structures in bridge construction, bending internal piping in ship assembly, shaping metal frame steel pipes in furniture production, and bending various metal decorative pipes in decoration and renovation. All these tasks require the assistance of automatic pipe bending machines.

3. Classification of Automatic Pipe Bending Machines

Automatic pipe bending machines can be broadly classified into manual pipe bending machines, CNC pipe bending machines, and hydraulic pipe bending machines. Manual pipe bending machines rely primarily on manual operation for bending, offering relatively simple operation and suitability for small-batch, simple-angle bending needs. CNC pipe bending machines control the bending process through computer programs, enabling precise bending at preset angles and shapes, with a high degree of automation. Hydraulic pipe bending machines utilize hydraulic power to provide bending force, handling the bending of thicker and more robust steel pipes with strong and stable power.

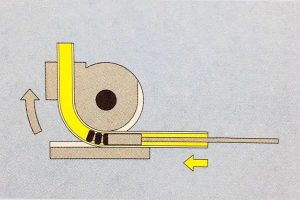

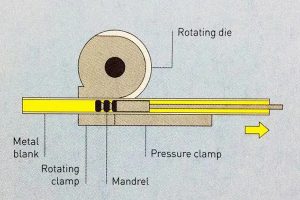

4. Principle of Automatic Pipe Bending Machines

The principle of automatic pipe bending machines is key to achieving precise bending of steel pipes. During operation, the metal pipe is first firmly fixed in a rotating clamp using a shaft. This fixing process ensures the pipe does not loosen, laying a stable foundation for subsequent bending. Then, the rotating clamp will rotate in a circle around the center of the turntable. While rotating, the mandrel will provide support from the inside of the tube to prevent the tube from denting or deforming due to lack of internal support when bending. The rotating clamp will apply a uniform force from the outside of the tube. The mandrel and clamp will form a force that works together. Under the combined action of these two forces, the metal tube will be bent into a certain angle according to the preset trajectory, thereby achieving the desired bending effect.

|

|

5. Cold Bending and Hot Bending Methods of Pipe Bending Machines

In actual production, due to the varying materials, specifications, and bending requirements of steel pipes, many different pipe bending processes have emerged. In engineering, pipe bending processes are typically categorized into two main types based on whether the steel pipe is heated during bending: cold bending and hot bending. Furthermore, based on whether the steel pipe is filled with a filler material during the bending process, it can be further divided into cored bending and coreless bending. Generally, for stainless steel pipes, especially thin-walled stainless steel pipes, because these pipes have good plasticity at room temperature and can withstand bending forces in a cold state, and because heating can easily lead to oxidation on the pipe surface, affecting appearance and performance, and may also alter the internal structure of the pipe, reducing its strength and other properties, the bending of thin-walled stainless steel pipes is primarily carried out using the cold bending method.

(1) Cold Bending Method

The core characteristic of the cold bending method is that the pipe is bent at room temperature without the need for heating. Because no heating is required when using an automatic pipe bending machine for cold bending, it does not adversely affect the properties of materials such as stainless steel, aluminum, and copper pipes. For example, it does not cause oxidation, discoloration, or strength reduction in these pipes. Therefore, it is more suitable for bending stainless steel, aluminum, and copper pipes. Commonly used cold bending methods include roll bending, stretch bending, push bending, and pressure bending. Roll bending uses multiple rollers to gradually compress the pipe, causing it to slowly bend into the required arc. Stretch bending involves fixing one end of the pipe and then pulling the other end with external force, causing the pipe to bend around a specific mold. Push bending applies a pushing force from one end of the pipe, causing it to bend along a preset mold trajectory. Pressure bending uses a mold to directly apply pressure to specific parts of the pipe, forcing it to bend. Different cold bending methods are suitable for different pipe specifications and bending requirements.

(2) Hot Bending Method

Unlike cold bending, hot bending typically uses either flame heating or medium-frequency power supply heating to heat the part of the pipe to be bent to a certain temperature. Once the pipe reaches a suitable bending temperature, it is then bent. Hot bending significantly increases the plasticity of the pipe at high temperatures, allowing for larger bends and meeting the needs of large-angle bends in special applications. Furthermore, hot bending ensures good roundness at the pipe end, preventing obvious elliptical deformation; the overall flatness of the bend is also high, preventing significant warping; and the bending angle is precise with minimal error. During bending, the pipe wall thickness reduction rate is relatively small, better preserving the original wall thickness and ensuring the strength of the bend. In addition, hot bending effectively eliminates residual stress generated during bending, preventing it from affecting subsequent use and ensuring the pipe’s load-bearing capacity, allowing it to withstand various external forces in the environment.

6. Demand for Bending Machines for Complex Processes

In daily life, the finished steel pipes we encounter are far more complex than simple angle bends. The simple steel pipe bending process mentioned earlier represents only the basics of pipe bending. In practical applications, many steel pipes require much more complex bending effects. For example, some pipes in automotive fuel systems not only require multiple bends at different angles but also need to form specific three-dimensional orientations to adapt to the complex interior layout of the car; some pipes in air conditioning systems may require continuous arc bends with varying bending radii. These complex steel pipe bends require combining the multiple functions of automatic pipe bending machines with different bending processes. During processing, the appropriate type of pipe bending machine and bending process are selected based on the specific bending requirements of the steel pipe. For example, the precise control function of a CNC pipe bending machine is used in conjunction with cold or hot bending processes, and core bending may also be incorporated to ensure the stability and bending accuracy of the pipe during complex bending processes, ultimately completing the complex steel pipe bending process and meeting practical application needs.

Our website features many different types of pipe bending machines. If you are unsure which model to choose, please feel free to contact us bender@antishicnc.com. Our professional sales staff are always ready to assist you.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.