One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.

Many years of production experience, high-quality machines

Factory direct sales, welcome to visit the factory

24-hour telephone, email online service.

No installation required, simple operation, support video teaching

| Type | BL-3D-51200 Parameter | Main parts name | Brand | Origin | |

| Applicable Wire Dia. | Soft material Φ:5.0-12.0mm | servo motor | SANYO /YASKAWA | Japan | |

| Hard material Φ:5.0-8.0mm | |||||

| Processing stroke | 650mm | Linear slide | HIWIN | Taiwan | |

| Number of control axes | 5 Axis | Rotary arm reducer | Tai Cheng | Taiwan | |

| Power Of Roating arm Motor | 4.5KW | Angle folding reducer | Tai Cheng | Taiwan | |

| Power Of wire Feeding Motor | 7.5KW | Lifting reducer | NEUGART | Germany | |

| Power Of angle folding motor | 2.0KW | Bearing | NSK/IKO | Japan | |

| Power Of wire I/O (forward-backard) motor | 1.0KW | Inverter | Huichuan | Shenzhen | |

| Power Of wire cutting Motor | 1.0KW | computer system | Topcon | Guangdong | |

| Max,wire feeding speed | 50m/min. | Machine Base material | A3 steel | Guangdong | |

| Wire feeding accuracy | 300mm±0.1mm | Remark: | |||

| Angle folding Accuracy | 90°±0.2° | 1. Applicable wire diameter 5.0-12.0mm is soft material, soft material tensile strength | |||

| Working Voltage | Three-phase 380V(±20V) | ||||

| Main machine weight | 4500kg | soft material tensile strength≤500N; | |||

| Machine size(L*W*H) | 3800×2200×2000mm | 2. Applicable wire diameter 5.0-8.0mm is hard material, | |||

| Automatic wire feeder | Maximum load Weight | 2000Kg | |||

| Diameter of Round Tray | φ2000mm | hard material tensile strength≤1700N。 | |||

| Motor Power | 2.2KW | 3.The distance between the wire feeder and the main wire bending machine is 2000mm | |||

| Weight | 1600Kg | ||||

| Size (L*W*H) | 2400*2400*1600mm | ||||

Equipment features:

1. Computer control system and imported servo motors are used.

2. The computer has Chinese and English (optional) interfaces, is easy to operate, has accurate positioning, and all motors can run synchronously or separately.

3. The wire feeding box uses four sets of synchronous wire feeding, and has its own precision detection device to ensure the accuracy and stability of wire feeding.

4. According to the working conditions on the display screen, the angle, length, parameters, etc. of the product can be corrected.

5. When there is no wire, wire breakage, or entanglement, there is an automatic shutdown design and automatic acceleration function of the wire rack, making production easier and more effective.

6. Suitable for the production of: car seat frames, sun visor frames, car door lock rods, handicraft metal wires, kitchen utensils and tableware brackets, storage cages, supermarket trolleys, supermarket shelves and other wire forming products.

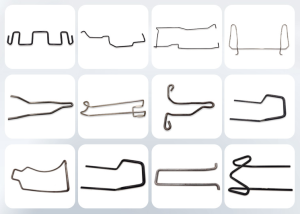

Case drawing display:

Applicable to the production of automobile seat frames, sun visor frames, automobile door lock pull rods, handicraft metal wires, kitchenware and tableware stands, storage cages, supermarket trolleys, supermarket shelves and other wire forming products.

Youtube Channel : Antishicnc Machine