One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.

Many years of production experience, high-quality machines

Factory direct sales, welcome to visit the factory

24-hour telephone, email online service.

No installation required, simple operation, support video teaching

| Model No.

Item |

BL-3D-6250 Parameter |

| Wire diameter of production | Soft material:1.6mm-3.5mm

Hard material:1.6mm-2.5mm |

| Processing stroke | 700mm |

| No of control axes | 6 Axes |

| Total Power | 5.6KW |

| Power of wire feeding motor | 2.0KW |

| Power of Rotary arm motor | 2.0KW |

| Power of lifting motor | 0.4KW |

| Power of curl servo motor | 0.4KW |

| Power of curl lifting servo motor | 0.4KW |

| Power of cutting servo motor | 0.4KW |

| Working voltage | Three-phase 380V (±20V) |

| Machine size(L*W*H) | 1900mm*1600mm*1700mm |

| Weight of main machine | 1200KG |

| Wire rack bearing weight | 200KG |

Equipment features:

1. Computer axis card control system is adopted.

2. The arcs at the front and rear ends of the foamed steel wire are tightly closed.

3. The computer has Chinese and English (optional) interfaces, which are simple to operate and accurate in positioning. All motors can run synchronously or separately.

4. It is more convenient to debug and switch products, without frequent replacement of tooling fixtures, and the forming space is more flexible.

5. The product is formed by rotating the head, and 100-600mm long steel wire parts and asymmetric products (automobile foamed steel wire) can be formed.

6. The head rotation design can be flexibly rotated at high speed according to the specific product, improving product production efficiency.

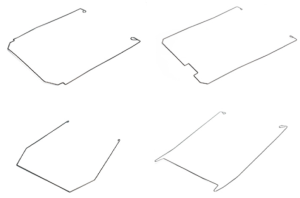

Case drawing display:

Applicable to the bending process of foamed steel wire

Youtube Channel : Antishicnc Machine