One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

First, what is a double-head pipe bender?

Double-head pipe bender is a professional equipment for pipe bending process, mainly composed of the body, bending mechanism, transmission system, control system and other components. The body is the support structure of the entire machine, usually using a strong metal frame to ensure the stability of the machine in the working process. Bending mechanism including bending die, clamping die and other components, is to achieve the key part of the pipe bending. The transmission system is used to transmit power so that the bending mechanism can move in accordance with the set manner and speed. The control system is the ‘brain’ of the machine, you can set the parameters of the bend, such as the bending angle, bending speed, pipe feed and so on.

Second, the working principle of the double-head pipe bender

At work, the pipe is placed on the machine’s worktable, and the pipe is fixed by the clamping mould. Then, two bending head (double head) driven by the transmission system, in accordance with the pre-set procedures and parameters, at the same time or successively on the pipe bending operation. For example, when processing a pipe with two bending parts, the two bending heads can start bending at both ends of the pipe at the same time, which can greatly improve the processing efficiency. During the bending process, the bending die exerts pressure on the pipe, causing it to gradually deform around the bending radius of the die, and ultimately forming the desired bending shape.

Third, the advantages of double-head pipe bender

| High efficiency | With two bending heads working at the same time, the double-head pipe bender can significantly reduce processing time when processing pipe fittings with multiple bending sections compared to a single-head pipe bender. |

| High precision | Double-head pipe bender is equipped with an advanced control system that can accurately control the bending angle, bending radius and pipe feed and other parameters |

| Wide range of applications | It can process pipes made of various materials, such as stainless steel pipe, carbon steel pipe, copper pipe, etc.. And can adapt to different pipe diameters and wall thicknesses of the pipe, the pipe diameter range is generally from a few millimetres to tens of millimetres, the wall thickness can be from zero a few millimetres to several millimetres. |

Fourth, case study – SW50NC double-head hydraulic pipe bender

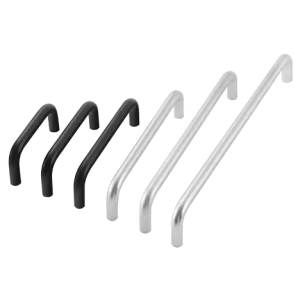

Recently, we received a machinery manufacturer from Peru, he needs to manufacture a number of handrails, mainly used in hospitals, nursing homes, schools and other public areas, made of stainless steel, diameter 30-45mm, thickness 0.5-1.5mm, length 300-1500mm, according to the customer’s needs, our company’s engineers to match the customer with a SW50NC double-head hydraulic Bender, can meet the needs of customers.

The technical parameters are as follows:

| Description | SW50NC |

| Max Bend Diameter X wall thickness (mm) | Φ 50×2 (carbon steel) |

| Max bending range (mm) | 40-200 |

| Max bending angle (deg) | 185º |

| Double bend center range (mm) | 250-2500 |

| Bending accuracy (+/-Deg ) | 0.1 |

| Bending speed (/sec) | 50º |

| Oil pump displacement (L/min) | 28 |

| Oil tank capacity (L) | 260 |

| Motor power (kw) | 7.5 |

| Hydraulic system pressure (MPa) | 14 |

| Machine size (L*W*H) (mm) | ≈4000×1000×1600 |

| Machine Weight (kg) | ≈2000 |

Keywords: Pipe bender, Double head pipe bender, Handrail processing special pipe bender

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.