One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Pipe bending machine is a common metal processing equipment, its main purpose is to bend metal pipes into pipes of different shapes. Pipe bending machines have the characteristics of simple operation, high work efficiency, high precision, and wide application range. Therefore, they are widely used in many fields, such as: construction field, energy field, automobile industry, shipbuilding industry, etc.

The key points for selecting a pipe bender are as follows:

1.Diameter range:

Determine the maximum and minimum diameters of the pipe you need to bend. Different models of pipe benders can handle different pipe diameter ranges. Make sure the selected pipe bender can adapt to your pipe size.

2.Wall thickness:

Consider the wall thickness of the pipe. Thicker pipes may require a pipe bender with higher power and stronger structure.

3.Material:

Carbon steel, stainless steel or others. Different materials have different hardness, which also affects the selection of pipe bends.

4.Minimum bending radius:

Determine the minimum bending radius required based on your product design requirements. Some pipe benders can achieve a smaller bending radius, while others may be limited.

5.Workpiece drawing:

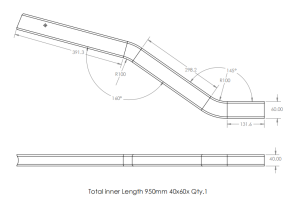

If you can provide product drawings, it will help us quickly recommend the selection for customers.

For example

In short, choosing a pipe bending machine requires comprehensive consideration of factors such as product specifications and production efficiency. During the selection process, it is recommended to communicate more with ANTISHICNC to understand the characteristics and advantages of different models of equipment so as to choose the pipe bending machine that best suits you.

If you need a pipe bending machine, please feel free to consult ANTISHICNC. We have rich industry experience and can provide professional suggestions based on your drawings and needs.

Tags: pipe bending machine, CNC bending machine, pipe bender

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.