One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Fully automatic pipe bending machines inevitably encounter defects during various pipe bending processes, such as springback at bends, wrinkling, bulging, and drag marks. These defects significantly impact the quality of the bent pipe fittings. Thinner pipe walls reduce the fitting’s ability to withstand internal pressure, affecting its performance. Distortion of the pipe’s cross-sectional shape can reduce the cross-sectional area, increasing fluid flow resistance and affecting the fitting’s structural functionality.

In addition to developing various types of fully automatic pipe bending machines, we also investigate the causes and countermeasures for defects like wrinkling, bulging, and drag marks caused by incorrect adjustment of the machine’s components.

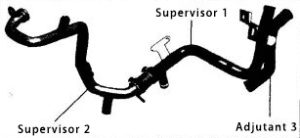

For example, consider an automotive coolant hose, as shown in Figure 1. One end of the hose connects to the engine cylinder head water jacket, and the other end connects to the radiator inlet. The entire hose consists of main pipe 1, main pipe 2, and auxiliary pipe 3, connected by a flexible hose.

Processing Defects and Countermeasures

When pipe fittings are processed on a fully automatic pipe bending machine, some shape defects may occur due to incorrect positioning of the machine’s components. The various shape defects, their causes, and corresponding countermeasures are summarized below.

1. Problem:Protrusion at the end of the bent pipe.

Cause: Mandrel too far forward.

Solution: Adjust the mandrel to the appropriate position.

2. Problem:Wrinkling at the bend.

Causes:① The pipe fitting is thin and no guide die was added. ② The guide die was not placed in the diameter die. ③ The guide die’s angle is too steep. ④ The guide die is not tightened. ⑤ The guide die is damaged.

Solutions:① Add a guide die. ② Adjust the position of the guide die. ③ Adjust the angle of the guide die. ④ Tighten the guide die forward. ⑤ Modify the guide die.

3. Problem:Protrusion on the outer side of the bend.

Causes: ① The clamping force of the guide die is too large. ② The distance between the two balls of the mandrel is too large. ③ The pipe material is too thin or unsuitable.

Solutions: ① Loosen the guide mold slightly. ② Replace the mandrel (with a smaller distance). ③ Change the pipe material.

4. Problem: The outer side of the bend is flat and there are severe drag marks at the clamping point.

Causes: ① Insufficient clamping force. ② Lack of lubrication, resulting in sufficient resistance. ③ The guide mold clamping force is too large, causing the mold to slide.

Solutions: ① Increase the clamping force. ② Add lubricating oil. ③ Adjust the positions of the guide mold, rear guide mold, mandrel, etc.

5. Problem: Deep scratches at the rear end of the bend.

Causes: ① Insufficient rear guide mold angle. ② Insufficient lubricant.

Solutions: ① Adjust the rear guide mold angle to approximately 0.8–1.5°. ② Add lubricant.

If you have any questions or would like to learn more about fully automatic pipe bending machines, please feel free to contact us bender@antishicnc.com. Our team of professional sales staff will be happy to answer your questions.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.