One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Introduction to the Need for Fully Automatic Pipe Bending Machines

Pipe bending refers to the metal forming process of permanently bending a pipe or fitting. Pipe bending processes are categorized as die-type and dieless bending, and are also categorized as hot bending or cold bending based on the heating method. Factors influencing pipe bending include pipe wall thickness, the die, and lubricant. Typically, the blank used for pipe bending is round tube. However, square and rectangular tubes and fittings can also be bent to meet processing requirements.

Die bending, such as press bending or roll bending, is commonly used to form workpieces, using a die to achieve the bending effect. Straight tubes can be processed using a press brake to produce a variety of single- or multi-bend parts on demand. Depending on the ductility of the metal pipe, various processes can be used to form a variety of complex shapes. Dieless bending processes, such as three-roller bending, adjust the kinematics of the workpiece to achieve the bending surface independently of the tool. With the growing demand from heavy industries and manufacturing sectors such as oil and gas, pipelines, refineries, power, hydropower, food processing, electronics, shipbuilding, marine engineering, furniture, construction, and infrastructure, the demand for pipe bending materials is also increasing.

Innovative Forming Technologies for Fully Automatic Pipe Bending Machines

With the deepening of bending research, new bending methods are constantly emerging. A common example is push bending, a new method suitable for cold forming thin-walled short elbows. It can meet product specifications in a single forming step. It is not only highly efficient and high-quality, but also features a simple bending mold structure, greatly improving production efficiency.

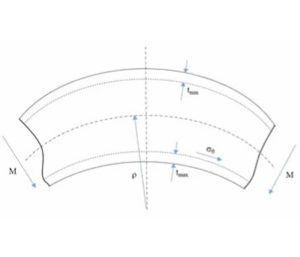

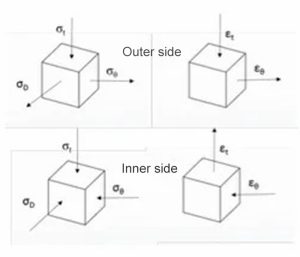

Pipe-type cold push bending involves placing the pipe into a corresponding bending mold and bending it under the action of a trolley. The forces acting on the pipe during the pure bending process are shown in Figure 1. The stress and strain states on the inside and outside of the pipe are shown in Figure 2. The inner wall thickness increases, the outer wall thickness decreases, and the internal microstructure of the material changes.

|

|

| Figure 1 | Figure 2 |

New fully automatic pipe bending machines with push bending functions can bend large radii and also help maintain cross-sectional shape. The advantage of the fully automatic pipe bending machine with push bending function is that it can achieve different bending radians on the same bent pipe product.

Automatic Pipe Bending Machine Operation Procedure

1. Standardized Pipe Shape: When designing and laying out pipes, avoid excessively large arcs, arbitrary curves, compound bends, and arcs greater than 180°. Excessively large arcs not only make the tooling bulky but also limit the size of the pipe bending machine. Arbitrary curves and compound bends are illogical in design and shape, significantly hindering mechanized and automated production and making it difficult for operators to relieve themselves from arduous manual labor. Arcs greater than 180° prevent the pipe bending machine from being able to remove the die.

2. Standardized Bend Radius: Bending radii should be standardized to the maximum extent possible, achieving “one die per pipe” and “one die per multiple pipes.” For a pipe, regardless of the number of bends or the bend angle, it can only have one bend radius. This is because the pipe bending machine does not change modules during the bending process; this is known as “one die per pipe.” “One die per multiple pipes” means that pipes of the same diameter should use the same bend radius whenever possible. This means using the same set of modules to bend pipes of different shapes, thus reducing the number of modules required.

3. Bend Radius: The size of the conduit’s bend radius determines the resistance encountered during bending. Generally speaking, larger pipe diameters with smaller bend radii are more prone to wrinkling and slipping during bending, making it difficult to guarantee bending quality. Therefore, it is generally recommended to select a bending die with an R value of 2 to 3 times the pipe diameter.

4. Bending Speed: The bending speed primarily affects forming quality: Too fast a speed can cause flattening of the conduit’s bend, substandard roundness, and cracking or breakage. Too slow a speed can cause wrinkling and slippage of the clamping block, leading to sagging in the bend for large-diameter pipes. Based on extensive testing on two CNC pipe bending machines, the optimal bending speed for conduits is 20% to 40% of the machine’s maximum bending speed.

5. Mandrel and Position: The mandrel primarily supports the inner wall of the conduit’s bend radius during bending, preventing deformation. Without a mandrel, pipe bending quality cannot be guaranteed on a machine. Mandrels come in many different styles, including cylindrical mandrels, universal mandrels with single, double, triple, or quadruple ball tips, and directional mandrels with single or multiple ball tips. Furthermore, the position of the mandrel also influences the bending process. Theoretically, its tangent line should be flush with the tangent line of the bending die, but extensive testing has shown that a 1-2mm lead is optimal, resulting in optimal bending quality. However, excessive lead can result in a “goose head” effect on the outer wall of the bend.

If you have any questions, please contact us by sending a message or visit our official website to inquire about our products.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.