One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

1.Preparation before operation

1)Check the equipment status

Before turning on the pipe bending machine, carefully check whether all parts of the equipment, including the fuselage, hydraulic system, transmission parts, etc. are intact. Check for obvious signs of damage, looseness or leakage. For example, check whether the oil pipe is broken and whether the joints are tight to prevent hydraulic oil leakage during operation.

Check the electrical system to ensure that the wires are not damaged, the plugs are firmly connected, and the equipment is well grounded to avoid electric shock accidents.

2)Mold installation and inspection

Select a suitable pipe bending mold according to the diameter, material and bending radius of the pipe to be bent. When installing the mold, make sure that the mold is installed correctly and firmly. For example, check whether the fixing screws of the pipe bending mold are tightened to prevent the mold from loosening during the pipe bending process, affecting the bending accuracy or even damaging the equipment.

For new molds or molds that have not been used for a long time, clean the mold surface, remove possible impurities such as rust and oil, and ensure good contact between the pipe and the mold.

3)Pipe preparation

The quality and size of the pipe have a great influence on the bending effect. Make sure that the material of the pipe is uniform and has no obvious cracks, sand holes and other defects. Measure the outer diameter and wall thickness of the pipe to ensure that its size meets the processing range of the pipe bending machine.

Clean the surface of the pipe to remove oil, rust and other impurities to avoid damaging the surface of the pipe or affecting the service life of the mold during the bending process.

2.Points to note during operation

1)Parameter setting

According to the requirements of the material, outer diameter, wall thickness and bending angle of the pipe, correctly set the working parameters of the pipe bending machine. This includes the pressure of the hydraulic system, bending speed, etc. For example, for thicker-walled pipes, it may be necessary to increase the hydraulic pressure appropriately, but it should also be noted that it should not exceed the rated pressure of the equipment to avoid damage to the equipment.

When setting the bending angle, use an accurate angle measurement tool for calibration to ensure the accuracy of the bending angle.

2)Operating specifications

Before starting the pipe bending machine, ensure that the operator is in a safe position to avoid accidental injury at the moment of equipment startup.

Place the pipe correctly in the mold so that it is aligned with the center line of the mold to ensure that the force on the pipe is uniform during the bending process. During the bending process, do not touch the pipe and the running equipment parts at will to prevent pinching or entanglement.

Pay attention to the bending process. If the pipe is found to be abnormally deformed, the mold is loose, or the equipment makes abnormal sounds, the operation should be stopped immediately. For example, if you hear abnormal noise in the hydraulic system, it may be a pump failure or oil circuit blockage, which needs to be checked in time.

3)Safety protection

Operators must wear appropriate personal protective equipment, such as safety helmets, protective gloves and goggles. Goggles can prevent impurities on the surface of the pipe from splashing and injuring the eyes during the bending process, and protective gloves can prevent hands from being scratched by the edge of the pipe.

When the single-head hydraulic pipe bender is working, a guardrail or warning sign should be set around it to prevent unrelated personnel from approaching. Especially during the operation of the equipment, non-operating personnel are strictly prohibited from touching the equipment.

3.Maintenance and care after operation

1)Equipment cleaning

After the bending operation is completed, the equipment should be cleaned in time. Remove dust, metal debris and other impurities on the surface of the equipment to keep the equipment clean. For the pipe bending mold, clean the pipe debris and oil stains left on it to avoid corrosion of the mold.

Check the hydraulic oil level and oil quality inside the equipment. If the hydraulic oil is insufficient, add it in time; if the oil is turbid or contains impurities, consider replacing the hydraulic oil to ensure the normal operation of the hydraulic system.

2)Equipment inspection and maintenance

Check each component of the equipment to see if any component is worn or damaged during operation. Focus on checking vulnerable parts such as molds, fixtures, and seals of the hydraulic system. For slightly worn parts, repair or replace them in time to prevent the problem from further deteriorating.

Regularly perform comprehensive maintenance on the equipment, including lubricating various moving parts, checking the performance of the electrical system, etc. For example, regularly add lubricating oil to the transmission chain, guide rails and other parts of the equipment to ensure smooth operation of the equipment.

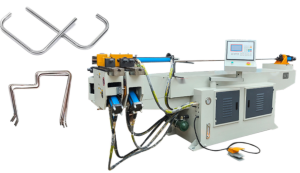

DW50NC is a hot-selling single-head hydraulic pipe bending machine from ANTISHICNC

| Main specifications | Unit | DW50NC |

| Max. bending diameter x Wall thickness | mm | Φ50×3.8 carbon steel

Φ48×3 Stainless steel |

| Max. bending radius. | mm | R200 |

| Mini. bending radius. | mm | R≥1.2D |

| Max. bending Angle. | Degree | 190 |

| Standard core length. | mm | 1800 |

| Control system | / | Microcomputer control |

| Number of elbow allowed for pipe fitting | Unit | 16 |

| Number of parts that can be stored | Unit | 16×16 |

| Oil motor power | KW | 5.5 |

| Max oil pressure | Mpa | 14 |

| Hydraulic system control | Solenoid valve | |

| Tank volume | L | 180 |

| Machine dimensions | mm | 3000*850*1150 |

| Machine weight | Kg | 1120 |

If you have similar processing needs, please feel free to consult ANTISHICNC. We have rich experience in pipe bending manufacturing and application, and can provide you with professional technical support.

Keywords: Single-head hydraulic pipe bender,Hydraulic pipe bending machine,Pipe-bending-machines

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.