One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

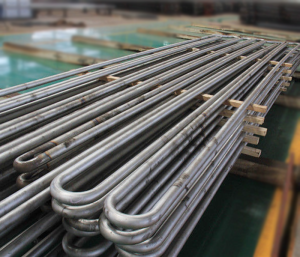

Serpentine tubes are used in many fields due to their efficient heat exchange and flexible spatial adaptability: in the power industry, in the boilers of thermal power plants, serpentine tubes can greatly expand the heating surface, quickly convert water into high-temperature steam, and efficiently realize the conversion of heat energy into electrical energy. In chemical production, the serpentine tubes in the reactor and the heat exchanger are flexibly arranged according to different process flows, which can not only accurately control the reaction temperature and accelerate the chemical reaction, but also efficiently transfer heat between different media to ensure the smooth operation of chemical production. In building HVAC systems, both central air conditioning in large shopping malls and household heating in residential buildings are used. In food processing workshops, serpentine tubes can quickly heat up and cool down during high-temperature sterilization to lock in food nutrients, and in the concentration process, they can efficiently evaporate solvents and improve production efficiency.

However, there are many difficulties in bending serpentine tubes. First of all, the complex spatial shape of the serpentine tube places extremely high demands on the bending process. It contains multiple bends with different curvature radii. During the bending process, the bending angle and radius of each part need to be precisely controlled. Secondly, the material properties increase the difficulty of bending. Metal materials commonly used to manufacture serpentine tubes, such as stainless steel and heat-resistant alloy steel, have high strength and a certain tendency to work hardening. When bending, the material is difficult to deform, which not only easily causes defects such as wrinkles and cracks, but also changes the material properties due to work hardening, reducing the service life of the pipe. Furthermore, the accuracy and stability of the bending equipment are crucial. Ordinary bending equipment is difficult to meet the high-precision bending requirements of serpentine tubes.

|

|

For this type of serpentine tube, especially boiler tubes with long tubes and thick walls, ANTISHICNC has specially designed a CNC double-head left and right tube bending machine:

| Basic technical data | Unit | CNC80RLHM-D+SBH-5A | |

| Max bending capacity round pipe mild steel>1.5D | mm | Φ80×3.5 | |

| Max bending capacity round stainless pipe>1.5D | mm | Φ80×2.0 | |

| Number of die stack | Stacks | Multi-stack | |

| Max feeding trip | mm | 6000 (customizable) | |

| Feeding center height | mm | 1250 | |

| Feeding method | mm | Direct or clip | |

| Range of bending radius | mm | 300 (customizable) | |

| Angle of Max bending | degree | 190° | |

| The number of pipes can be set per pipe fittings | bends | 50 | |

| Working speed | Y axis Pipe feeding speed | mm/second | Max.700mm |

| B axis Pipe rotating speed | degree/second | Max.90° | |

| C axis Pipe bending speed | degree/second | Max.35° | |

| X axis Machine head left and right displacement moving speed | mm/second | Max.150mm | |

| Operating accuracy | Bending angle (repeated) | degree | ±0.1° |

| Transfer angle (repeated) | degree | ±0.05° | |

| Delivery length (repeated) | mm | ±0.05mm | |

| Data input method | Coordinate value (XYZ) or working value(Y B C) or 3D | ||

| Y axis-Tube feeding servo motor power | KW | 2.9 | |

| B axis- Tube rotating servo motor power | KW | 1.8 | |

| Z axis-Left and right machine head up & down movement servo motor power | KW | 5.5*2 | |

| X axis-Left and right machine head left & right movement servo motor power | KW | 5.5 | |

| Right & Left tube hydraulic bending motor power | KW | 15.0 | |

| Machine gross weight | kg | 10500 | |

| Machine size L.W.H | mm | 9500X3400X2010 | |

If you have similar serpentine tube bending requirements, please contact Shanghai ANTS Machine, we will provide you with professional technical support and solutions!

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.