One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

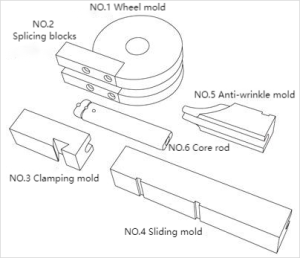

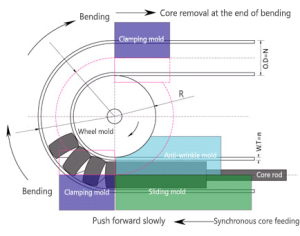

In the realm of metalworking, the installation of the tube bending machine mold is a procedure of utmost significance. It directly impacts the quality and precision of tube bending, as well as the production efficiency and the service life of the equipment. Here, we will not only delve into the installation steps and key considerations for the tube bending machine mold in detail but also clarify the crucial role of the mold. Additionally, we will provide schematic diagrams of the mold and the bending process to assist you in better understanding and mastering this technique.

|

|

1.The Role of the Mold

The mold in a tube bending machine is the essential tool that determines the shape and quality of the bent tube. It acts as a form-giving element, dictating the curvature, radius, and overall geometry of the tube during the bending process. Without a proper mold, achieving accurate and consistent bends would be impossible. The mold provides the necessary support and guidance to the tube, ensuring that it is deformed in a controlled and precise manner. It helps in maintaining the desired diameter and thickness of the tube throughout the bending operation, preventing wrinkling, flattening, or other deformations that could compromise the structural integrity and functionality of the final product. Different molds are designed for various bending radii and tube sizes, allowing for a wide range of applications in different industries such as plumbing, automotive, and aerospace.

2.Installation Steps

Power Off: Ensure that the tube bending machine is in a power-off state to guarantee the safety of the installation process.

Equipment Cleaning: Clean the dust, debris, and residual metal chips on the surface of the tube bending machine to provide a clean environment for mold installation.

Tool Preparation: Prepare the necessary tools such as wrenches, and check their integrity and applicability.

Mold Inspection: Carefully examine the mold for any damage, such as cracks or deformations in the bending part and the integrity of the fixing holes. Ensure that the mold is of qualified quality and matches the tube bending machine.

Fixed Mold Installation

Accurately place the fixed mold (upper mold or stationary mold) on the corresponding position of the tube bending machine, using the positioning pins or slots to ensure correct positioning.

Firmly fix the fixed mold on the tube bending machine with bolts according to the specified torque, avoiding over-tightening or under-tightening.

Movable Mold Installation

Install the movable mold (lower mold or movable mold) on the movable part of the tube bending machine, ensuring precise cooperation with the fixed mold.

Connect the movable mold to the drive device of the tube bending machine, such as hydraulic or mechanical transmission components, to ensure a reliable connection.

|

|

Mold Debugging

After installation, manually operate the tube bending machine first to check whether the opening and closing actions of the mold are smooth and without interference.

Conduct a preliminary bending test, use test tubes to check whether the shape and angle of the bent tube meet the requirements, and fine-tune the mold according to the results.

Final Inspection

Recheck the tightness of all bolts to ensure that the mold is firmly installed.

Check whether the clearance between the mold and other components of the tube bending machine is appropriate to avoid collisions.

Power-on Operation

After confirming that the installation and inspection are correct, power on the electric or CNC tube bending machine.

Function Check (for CNC Tube Bending Machines)

After the CNC tube bending machine is powered on, perform simple programming operations to set the bending parameters.

Check whether the tube bending machine can operate normally according to the set parameters to verify the compatibility of the mold installation and the control system.

Record information such as the mold model, installation date, and bending parameters during debugging for future maintenance and problem troubleshooting.

3.Key Considerations

| Safety Matters | Follow safety procedures and wear proper gear (like gloves).Use proper lifting if molds are heavy to prevent dropping. |

| Precision Assurance | Ensure a flat installation surface for accurate mating.Align installation holes correctly; check with precision tools if needed. |

| Compatibility | Select the right mold for the machine’s type and specs.Know the machine’s parameters and choose a suitable mold. |

| Lubrication & Maintenance | Lubricate key parts before installation.Clean and maintain regularly to prevent rust and wear. |

| Pressure Adjustment (Hydraulic Machines) | Set the right hydraulic pressure according to the mold.Monitor pressure for any abnormal changes. |

| Mold Surface Protection | Avoid scratches and collisions during handling.Use proper handling methods and store with protection. |

| Mold Storage | Store in a dry and ventilated place.Inspect regularly for rust and damage. |

If you need a pipe bending machine, welcome to consult Shanghai ANTISHICNC. We have rich experience in manufacturing and and application of pipe bending machine, and can provide you with professional technical support.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.