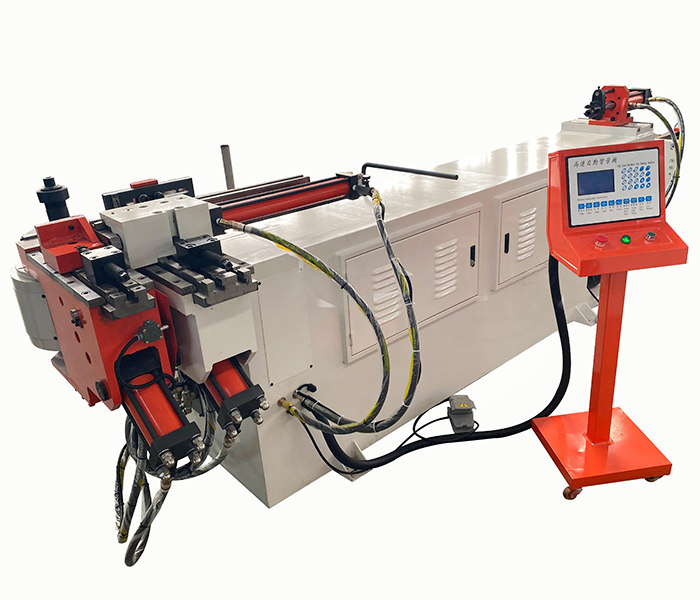

One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

What should be done to reduce the thickness of pipe bending machines? First of all, it should be clear that the performance of pipe bending machines is different, and there are different requirements for the wall thickness thinning rate. For example, pipe fittings are used in industrial pipeline projects, and no more than 10% are high-pressure pipes. The number of medium and low-pressure pipes should not exceed 15%, and should not be less than the designed calculated wall thickness.

Measures to reduce the thickness of pipes are:

1. Reduce the tensile stress value at the location where tensile deformation occurs outside the neutral layer. For example, the method of local heating with resistance is used to reduce the deformation resistance of metal materials inside the neutral layer, so that the deformation is more concentrated in the compressed part, so as to achieve the purpose of reducing the stress level of the tensile part.

2. Change the stress state of the deformation zone and increase the compressive stress component. For example, changing from a round bend to a push bend can fundamentally overcome the defect of transitional thinning of the pipe wall.

The actual bending moment when the pipe is bent depends not only on the performance, cross-sectional shape and size, bending radius and other parameters of the pipe, but also has a lot to do with the bending method and the mold structure used. Therefore, it is currently impossible to express many factors using calculation formulas and they can only be estimated during the production process.

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.