One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

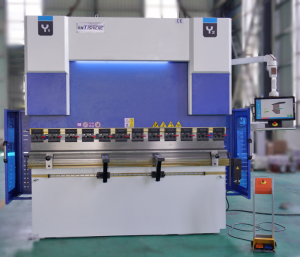

A bending machine is an important piece of equipment in the sheet metal processing industry. It can apply pressure to metal sheets, causing them to undergo plastic deformation at specific locations, thereby producing sheet metal parts of various shapes and angles.

Bending machines are widely used in various industries: for example, in the chassis and cabinet industry for distribution boxes, control cabinets, server cabinets, network cabinets, and industrial control consoles; in the elevator and escalator industry for elevator car panels, door panels, and decorative panels; in the automotive and transportation industry for truck/van frames and body panels, and bus body frames; in the construction and agricultural machinery industry for excavators, cranes, tractors, and other large equipment covers, protective covers, and cabs; in the home appliance and kitchenware industry for refrigerator, washing machine, and air conditioner housings; in the construction and decoration industry for metal roofs, curtain wall systems, aluminum alloy doors and windows, metal partitions, and stair treads; in the communications and electronics industry for 5G base station housings, radar covers, electronic instrument housings, and equipment brackets; and in the furniture and display industry for metal desks, shelves, display stands, and shopping mall display cases. They are used in almost all industrial fields requiring metal structural components and some non-industrial fields.

All these bending needs across various industries rely on bending machine mold. So, what issues should we pay attention to when selecting mold when purchasing a bending machine? Let’s take the actual situation of one of our customers who has already purchased a bending machine as an example:

1.Provide the factory with the workpiece drawings that need to be bent, and the factory’s technical staff will recommend suitable molds based on the drawings.

2.Communicate all workpiece types to be bent as early as possible to avoid purchasing separate molds later. Often, customers don’t provide drawings of the workpieces they need to be bent when purchasing the machine. In such cases, the factory usually only provides standard molds. However, after receiving the machine and starting to use it, the customer finds that the standard molds are insufficient. At this point, communicating about the workpiece drawings and purchasing separate molds wastes time and incurs additional mold transportation costs.

3.Specify your exact requirements for the mold, such as whether a segmented lower mold is needed. Typically, a segmented lower mold requires an additional mold holder to secure it, while a non-segmented lower mold can be directly secured using the machine’s built-in clamps. Segmented molds are suitable for bending very long or non-standard shaped workpieces, offering greater flexibility.

4.Before making the mold, communicate with the factory to confirm the mold drawings. Production should only be arranged after both parties have confirmed them to avoid the situation where the mold is unsuitable after production.

The image below shows the standard square mold provided by the customer and the T-shaped single-V mold that the customer plans to purchase separately for the second time.

|

|

| Standard square mold (for reference only) | T-type single V mold |

If you also need to bend workpieces of various shapes and require a bending machine, please feel free to contact Shanghai ANTISHICNC. We have professional engineers who can provide you with expert technical support.

Company email: bender@antishicnc.com

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.