One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

2D CNC wire bending machine: an innovative tool in the field of precision machining

2D CNC wire bending machine is an automated processing equipment that realizes the precise bending of metal wires in a two-dimensional plane through digital program control. It is based on computer programming, equipped with high-precision mechanical structure and servo drive system, and can bend various types of metal wires into specific geometric shapes according to preset paths and parameters. It is widely used in mass production from simple parts to complex components, and is one of the key equipment for metal wire processing in modern manufacturing.

Ⅰ. Processing advantages

1. Ultra-high precision processing control

The equipment adopts a closed-loop servo control system, which shows excellent performance in the control of bending angle and wire feeding length. The control accuracy of the bending angle can be stabilized within ±0.1°, and even for complex workpieces that require multiple bends, the cumulative error can be strictly controlled within the allowable range. The accuracy of the wire feeding length can reach ±0.05mm, ensuring that each wire can be accurately placed during the processing process, laying a solid foundation for subsequent bending processes. This high-precision feature enables it to meet the processing needs of fields such as aerospace and precision instruments that have extremely high requirements for part size.

2. Flexible and diverse adaptability

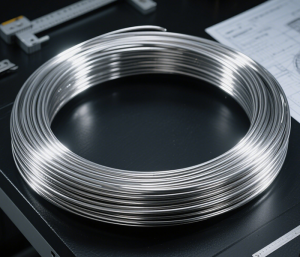

When processing wires of different specifications and materials, the two-dimensional CNC wire bending machine shows extremely strong adaptability. It can process a wide range of wire diameters, from ultra-fine wires of 0.2mm to thicker wires of 10mm. Whether it is non-ferrous metal wires such as copper and aluminum with good toughness, or carbon steel and alloy steel wires with high hardness, the equipment can automatically adjust parameters such as clamping force, bending speed and pressure to ensure the stability of the processing process, without problems such as wire breakage and excessive deformation.

3. Efficient production rhythm

Thanks to the fast-response servo motor and optimized program algorithm, the processing efficiency of the equipment is far ahead of traditional processing methods. For simple bending processes, the processing time of a single piece can be shortened to less than 1 second; even for complex parts with multiple bends, dozens of pieces can be processed per minute. At the same time, the equipment supports continuous and uninterrupted operation, and with the automatic feeding mechanism, it can achieve long-term unattended production, significantly improving the company’s production capacity.

4. Convenient programming and debugging

The dedicated programming software is easy to operate. The operator only needs to import the CAD drawings of the parts, and the software can automatically generate the processing code without manually writing complex programs. For some parts with special shapes, the manual teaching function can also be used to allow the equipment to record the operation trajectory and automatically generate programs, greatly shortening the debugging cycle of new products. In addition, the program can be stored in the device’s memory. When the same product is produced again, the program can be directly called, reducing the time for repeated debugging.

Ⅱ. Wide application in multiple fields

1. Furniture manufacturing field

In the production of various types of metal furniture, 2D CNC wire bending machines play an important role. For example, the frame of a metal seat usually requires bending a steel pipe with a diameter of 8mm into multiple right angles and arcs to ensure the load-bearing capacity and aesthetics of the seat. The equipment can accurately complete these bending processes according to the design requirements, and the seat frame produced has uniform size and stable structure. In addition, the connectors of the metal bed frame and the hanging rod bracket of the wardrobe can all be efficiently processed by it, which not only improves production efficiency, but also improves the overall quality of furniture.

2. Toy production industry

Many metal parts in toys, such as the chassis frame of toy cars and the joint connectors of deformable toys, have unique shapes and small sizes, and require high processing accuracy. The 2D CNC wire bending machine can easily complete the processing of these complex shapes, and the processed parts have a smooth surface and no burrs, which will not cause harm to children. At the same time, in view of the production characteristics of multiple varieties and small batches in the toy industry, the equipment can quickly switch production procedures to meet the processing needs of different styles of toys.

3. Aerospace accessories processing

In the field of aerospace, some small metal wire parts, such as the pointer skeleton in aircraft instruments and the line fixing bracket inside the spacecraft, have extremely strict requirements on precision and reliability. The two-dimensional CNC wire bending machine can process standard parts with its ultra-high processing accuracy and stable performance. For example, a titanium alloy wire bracket processed by an aerospace accessories company using this equipment has a key dimension error controlled within 0.03mm, which fully meets the use requirements of spacecraft and ensures the normal operation of accessories in extreme environments.

4. Sports equipment production

Many parts in sports equipment also rely on two-dimensional CNC wire bending machines for processing. For example, the frame of a badminton racket and the frame of a tennis racket are usually bent from high-strength carbon fiber composite wire. The equipment can accurately control the bending angle and curvature to ensure the elasticity and uniformity of the racket. There are also springs in fitness equipment, metal rods of tensioners, etc., which have stable performance and greatly extended service life after being processed by this equipment.

Ⅲ. Promote the transformation of processing mode

The emergence of two-dimensional CNC wire bending machines has changed the situation where traditional metal wire processing relies on manual labor and special molds. It makes small-batch and multi-variety production more economical and feasible. Enterprises do not need to make expensive molds for each product separately, reducing production costs and inventory pressure. At the same time, high-precision and high-efficiency processing capabilities also enable companies to respond to market demand more quickly and shorten the cycle from product design to mass production. In the global manufacturing competition, this type of equipment has become an important boost for companies to enhance their core competitiveness, and has continuously promoted the metal wire processing industry to develop in a more efficient, more precise and more flexible direction. If you need, please contact us bender@antishicnc.com , we have professional business personnel to answer your questions.

Learn More:

Application and advantages of pipe bending machines in furniture manufacturing

How to choose a fully automatic pipe bending machine suitable for shipbuilding?

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.