One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.

Many years of production experience, high-quality machines

Factory direct sales, welcome to visit the factory

24-hour telephone, email online service.

No installation required, simple operation, support video teaching

| Model

Item |

BL-YG-12A |

| Applicable Wire Dia. | Thick 4mm*width 9mm

Thick 4mm*width 12mm |

| Bending stroke | 500mm |

| No. Of Axis | 12 Axis |

| Total power | 55.9KW |

| Power of Wire Feeding Motor | 7.5KW |

| Power of Turning Motor | 4.4KW*2 |

| Power of Angle Control Motor | 4.0KW |

| Power of Inner Roll Motor | 2.5KW |

| (Front/rear) Motor Power | 1.8KW |

| Power of Lifting Motor | 4.0KW |

| Power of Wire Cutter Motor | 3.0KW |

|

(Front/rear) Wire Cutter Motor Power |

1.8KW |

|

Power of Ram Motor |

7.5KW*3 |

| Operating Voltage | Three-phase power |

| Size of Machine | 12000mm*2500mm*2400mm |

|

Weight of Machine |

16000KG |

| Load-bearing of Automatic Wire Feeder | 1000KG |

| BL-YG-12A Parts brand and Origin | ||

| Main part | Brand | Place of origin |

| Servo Motor | yaskawa |

Japan |

|

Reducer |

NEUGART |

Germany |

| Roating arm reducer | CST | Taiwan |

| Bearing | NSK/IKO/SKF | Japan |

| Bearing | FAG | Germany |

| Screw guide rail | HIWIN | Taiwan

|

| Computer system | YITU | Taiwan |

| Switch power supply | WEAM WELL | Taiwan |

| Frequency Convrter | Huichuan | Shenzhen |

| Circuit breaker | schneider | France |

|

AC-Contactor |

schneider |

France |

Equipment features:

1. The bending adopts internal and external synchronous bending, which can bend sideways, vertically, and twisted.

2. The cutting module has a pre-pressing function to prevent burrs on the cut and make the cut smooth.

3. The equipment comes with convex point pressing, punching, LOGO pressing, and cape repair (optional).

4. The wire feeding adopts 4 sets of 120 outer diameter wire feeding wheels, and the wire feeding has its own encoder to control the compensation wire feeding accuracy.

5. The straightening mechanism has a horizontal and vertical 11*2 straightening method. The straightening bearing is aligned according to the raw material contour, and the straightness fully meets the industry product requirements.

6. The equipment comes with an auxiliary wire feeding device, and one person can easily change the material.

7. The feeding rack adopts a double-head feeding rack. The equipment can install 2 rolls of material at the same time during automatic production, saving material change time.

8. The system adopts a dedicated industrial control system, which is simple and clear to operate and comes with Chinese and English interfaces (other languages can be customized)

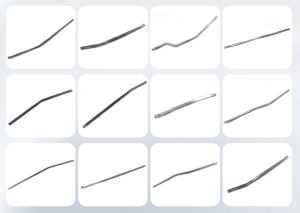

Case sample display:

Applicable to automobile wiper arm forming.

Youtube Channel : Antishicnc Machine