One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

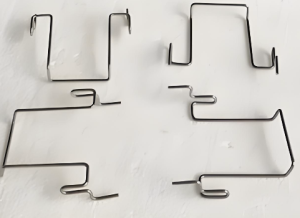

CNC wire forming machines have numerous applications, such as automotive seat frames, stainless steel decorative elements in home decoration, and kitchen and bathroom products.

CNC Wire Forming Machine Processing Methods

Currently, CNC wire forming methods mainly include bending, roll bending, and die bending (cold stamping).

Cold stamping requires specialized molds and cannot process complex three-dimensional (3D) wire parts, resulting in lower production efficiency. Similar to cold stamping, bending can cause material slippage on the wire surface, leaving processing marks and making it unsuitable for processing high-end parts made of materials like stainless steel. Roll bending equipment is relatively complex, but it produces higher processing quality. Bending and roll bending are common in automated production lines.

With the development of CNC and computer technology, wire forming processing has evolved from manual and semi-automatic methods to fully automatic CNC processing. Furthermore, PC-based, open CNC systems are gradually replacing traditional, dedicated CNC systems. From an implementation perspective, PC-based open CNC systems can be broadly categorized into four structural forms: PC-connected NC, PC-embedded NC, NC-embedded PC, and fully software-based. Among these, the NC-embedded PC type CNC system, which embeds an industrial motion control card and an industrial I/O card within an industrial PC, fully utilizes the PC’s software resources. Simultaneously, the motion control card performs interpolation and other calculations in hardware, without consuming PC hardware resources, enabling multi-axis (multi-coordinate), high-precision, and high-speed machining. It boasts advantages such as modularity, openness, and flexible programming, making it the mainstream approach for PC-based CNC systems.

Advantages of 2D CNC Wire Forming Machine

The 2D CNC wire forming machine is a highly efficient and precise tool in the field of metal wire processing. It integrates automatic wire feeding, intelligent straightening, precise forming, and automatic cutting, completely breaking through the efficiency bottlenecks and precision limitations of traditional processing methods.

Equipped with a servo motor drive and precision transmission system, the machine achieves a repeatability accuracy of ±0.01mm. Combined with a built-in intelligent calibration module, it easily overcomes industry pain points such as wire bending and human error, ensuring a product qualification rate consistently above 99%. Ordinary workers can operate the machine independently after 1-2 days of training, and one person can manage 2-3 machines simultaneously, significantly reducing labor costs. The modular design shortens mold changeover time to 5-10 minutes. It is compatible with various materials such as 0.3-6mm iron wire, steel wire, and stainless steel wire, and can mass-produce various products such as automotive parts, hardware brackets, furniture hooks, and medical components. Single-shift capacity is 3-5 times higher than traditional equipment, while energy consumption is reduced by 20%.

Fully automatic 2D wire forming machines are core equipment that helps manufacturing enterprises reduce costs, increase efficiency, and upgrade quality, making wire processing more efficient, precise, and worry-free. If you need a CNC wire forming machine, please contact us, and we will recommend the most suitable model for you.

Learn More:

Precautions for operating automatic wire bending machine

A Comprehensive Guide to Buying a Tube Bending CNC Pipe Bending Machine

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.