One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

In the precision machining field of modern manufacturing, CNC wire forming machines, with their superior automation and high-precision processing capabilities, have become core equipment for metal wire forming. Based on digital program control, they deeply integrate traditional wire bending and forming processes with advanced CNC technology, revolutionizing the traditional processing model that relied on manual operation or semi-automated equipment, providing efficient, stable, and precise wire forming solutions for various industries.

The Core Advantages of CNC Wire Forming Machines

The core advantage of CNC wire forming machines lies in their high degree of automation and precise control. Using pre-programmed CNC programs, the equipment enables precise control of parameters such as wire feeding, bending angle, and forming trajectory. Repeatable positioning accuracy can reach millimeters or even higher, effectively eliminating errors caused by manual operation and ensuring consistent product quality from batch to batch. Furthermore, features such as automated feeding and multi-axis machining significantly reduce manual intervention and significantly improve production efficiency, making them particularly suitable for mass production.

Technical Features of CNC Wire Forming Machines

In terms of technical features, CNC wire forming machines offer strong adaptability and flexibility. It is compatible with a variety of metal wire materials, including carbon steel, stainless steel, copper, and aluminum, meeting the specific material performance requirements of various industries. From simple straight and circular bends to complex three-dimensional forming, the machine can quickly switch processing options through program adjustments, eliminating the need for frequent mold changes. This significantly reduces product changeover time and provides strong support for small-batch, high-variety production needs.

Furthermore, modern CNC wire forming machines are generally equipped with intuitive human-machine interfaces and intelligent diagnostic systems. Operators can program, set parameters, and monitor production using the touchscreen, reducing the need for specialized technical expertise. Intelligent diagnostic functions monitor the machine’s operating status in real time, providing timely warnings of potential failures, minimizing downtime and ensuring production continuity.

Application Scenarios and Advantages of CNC Wire Forming Machines

CNC wire forming machines are widely used in a variety of fields, including automotive manufacturing, electronics, building hardware, medical devices, and aerospace.

Application Areas:

1. Automotive Parts: Forming various special-shaped wires such as car seat frames, door lock levers, car seat belt retainers, tension springs, springs, compression springs, car seat support wire parts, motorcycle and bicycle parts.

2. Household Hardware Wire Products: Forming kitchen display racks, storage racks, cabinet pull-out baskets, refrigerator shelves, supermarket shopping baskets, carts, and display pendants.

3. Wire crafts, lighting wire products, and fishing gear accessories, including wine racks and fruit baskets. 4. Cage Processing: Forming pet cages, bird cages, dog cages, breeding cages, and mouse traps. 5. Forming hooks for hangers, shoe racks, curtain racks, shelf racks, and display racks.

Features of the CNC Wire Forming Machine:

1. Single-shot forming

2. 7-axis workstation design without rocker arms or cams

3. Unique head rotation function for greater convenience, speed, and stability

4. Processable wire diameters: 3.0-9.0mm (hard material), 4.5-12.00mm (soft material)

5. Suitable for wire forming products such as automobiles and motorcycles

In terms of application advantages, firstly, in the automotive manufacturing industry, it can precisely process key components such as seat frames and airbag brackets, ensuring component dimensional accuracy and structural strength, thereby improving overall vehicle safety and reliability. Secondly, in the electronics and electrical appliance sector, it can efficiently form fine wires such as electronic component pins and connectors, meeting the growing demand for miniaturization and precision in electronic equipment. Furthermore, in the medical device industry, its burr-free, high-precision processing capabilities enable the production of surgical instrument accessories and wire structures for rehabilitation equipment that meet medical standards, ensuring the safety of medical equipment. Whether it is the precision wire structure of automobile seat frames, the pin forming of electronic components, or the special-shaped wire accessories in architectural decoration, it can achieve efficient processing, laying a solid foundation for product upgrades and quality improvements in various industries.

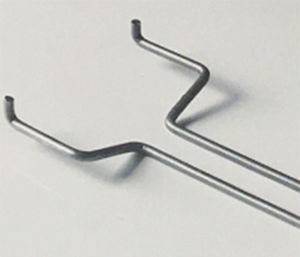

Product Image

|

|

As the manufacturing industry’s demand for precision machining continues to increase, CNC wire forming machines are developing towards higher precision, higher efficiency, and greater intelligence. We are committed to providing customers with high-performance CNC wire forming equipment and comprehensive technical support, helping companies optimize production processes, reduce costs, and enhance competitiveness. If you have any equipment needs or technical inquiries, please feel free to contact us. We will provide you with professional solutions and attentive service.

Previous Articles:

Application and advantages of 3D CNC wire bending machine

Application of automatic pipe bending machine in automobile field

How to choose a fully automatic pipe bending machine suitable for shipbuilding?

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.