One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

1. Overview of 2D Wire Forming Machine

2. Performance Characteristics of 2D Wire Forming Machine

3. Applications of 2D Wire Forming Machine to Various Industries

I. Overview of 2D Wire Forming Machine

The 2D wire forming machine is a planar 2D wire bending and forming machine. Various wire shapes of different specifications can be formed through different mold changes. There are servo feeding + hydraulic cutting combinations, servo feeding + servo cutting, and full servo combinations, selected according to the actual product size to achieve the highest cost-effectiveness. Chamfering, arc punching, and hole punching functions can also be added according to product needs to achieve wider application and use.

II. Performance Characteristics of 2D Wire Forming Machine

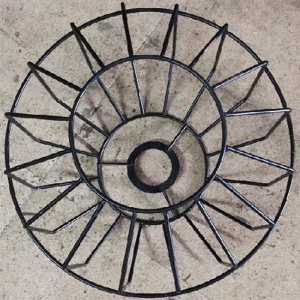

(1) External Structure Layout: This equipment features a planar design, professionally used for the forming design of frame-shaped, star-shaped, and other various 2D shapes of round and flat wires. The servo + spring housing is integrated with the machine body, combined with CNC precision machining, making the whole machine flexible, stable, efficient, and labor-saving. (2) Components: This equipment integrates wire straightening, clamping, precise wire feeding, forming, and cutting in one continuous process.

(3) Forming Precision Control: This equipment allows for programmable control of part precision requirements to meet the diverse forming needs of different wire shapes.

(4) Memory System: This equipment has a memory storage function, saving processing recipes. For subsequent processing, the recipe can be directly retrieved to complete the wire forming process. It can store 2048 programming files.

(5) Control System: The 2D CNC wire forming machine control system offers multiple manual, semi-automatic, and fully automatic functions, facilitating multi-functionality. A 32-bit high-performance processor can store 2048 programming files with a precision of 0.01 (lead screw precision up to 0.001), providing powerful functionality while reducing equipment investment and production intensity.

III. 2D wire forming machines are suitable for various industries.

|

|

(1) Automotive parts: Child seat frames, door lock levers, serpentine springs (including single and double serpentine springs), car head springs, sun visor rails, car seat wire, motorcycle parts, bicycle parts, car body production, etc.

(2) Daily hardware products: Kitchen display racks, storage racks, egg holders, cabinet baskets, refrigerator racks, bathroom display racks, etc.

(3) Wire crafts, lamp molding products, fishing gear parts, wine racks, family fruit plates, garden flower stands, Christmas wire gifts, etc.

(4) Processing of various cages: Bird cages, dog cages, pet cages, breeding cages, mouse traps, etc. Clothes hangers, shoe racks, curtain hooks, shelf hooks, display rack hooks, and other hooks.

(5) Production supplies: Warehouse shelves, wire mesh, hooks, display racks, assembly line products, etc.

The 2D wire forming machine not only greatly reduces labor costs but also increases efficiency by 4-5 times compared to traditional machines. 2D wire forming machines utilize CNC technology and, through programming, can precisely process various complex shapes.

If you have any needs or questions about 2D wire forming machines, please feel free to contact us bender@antishicnc.com. Our professional sales staff will provide you with detailed answers.

Learn More:

Why Choose a Suitable Semi-Automatic Pipe Bending Machine

How to solve defects in fully automatic pipe bending machine processing?

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.