One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

The function of a pipe bender is very simple. As the name suggests, it bends pipes. However, it may be different types of equipment in different application environments. For example, in many application scenarios, a profile rolling machine is also called a pipe bender. For example, the bending of a roller coaster track is actually an application of a profile rolling machine.

Processing application of pipe bending machine:

Pipe bending machine (cold bending machine) is also an essential equipment for tunnel construction at present. It is mainly used for cold processing of steel arch frames and is an ideal equipment for steel arch frame manufacturing. Pipe bending machine (cold bending machine) can perform cold processing on rectangular tubes, square tube steel pipes, round tube steel pipes, rails, I-beams, and H-steels. This equipment has the advantages of high efficiency, no need for hot processing, high strength of processed arch frames, and convenient transportation. It is widely used in pipeline production in power construction, boilers, bridges, ships, railway construction, decoration, etc. It has the advantages of multiple functions, reasonable structure, simple operation, easy movement, and fast installation.

Working principle of pipe bending machine:

Put the steel pipe on the pipe bending machine, and after it contacts the roller driven by the reducer, lock the clamping handle, start the motor oil pump group, and the high-pressure oil output by the electric oil pump passes through the overflow valve (the required pressure can be adjusted) and enters the electro-hydraulic valve. The electro-hydraulic valve and the inching switch (inching, inching) control the cylinder to work. The working cylinder advances and starts counting when the I-beam and the three supporting rollers are pressed tightly without bending deformation. The length of the cylinder in the advancement process is 10mm-15mm each time. Turn on the main motor forward or reverse, and the main motor drives the I-beam to work. Repeat the operation until the required amount is achieved.

Introduction to the pipe bending machine system:

1. Mechanical system: The mechanical system uses a cycloidal pinwheel reducer to directly drive the roller to rotate. In order to achieve synchronization between the two rollers, two motors are started at the same time to achieve synchronization. In order to meet the working conditions, it can be operated in forward and reverse directions.

2. Hydraulic system: The system uses a manual reversing valve to reverse the cylinder to achieve forward and reverse movement of the cylinder. A one-way throttle valve is used to adjust the movement speed of the cylinder. The two-way hydraulic control one-way valve is used to lock the cylinder. When the reversing valve is in the middle position, the system is unloaded, which effectively prevents the system from heating up.

3. Electrical system: The electrical system mainly controls the oil pump motor and the travel motor. The travel motor is equipped with forward and reverse control and overload protection. When the return oil filter is blocked and the filter element needs to be replaced, the filter blockage indicator light is on. At this time, the filter element must be replaced. An air switch (main switch) is set in the main return oil circuit to effectively protect the entire system.

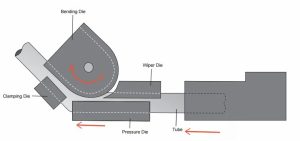

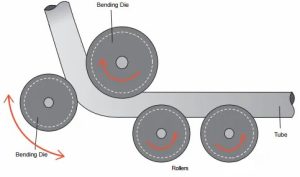

Choose the appropriate pipe bending method:

So when I have a pipe bending part to produce, how should I choose the appropriate pipe bending method?

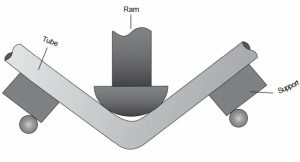

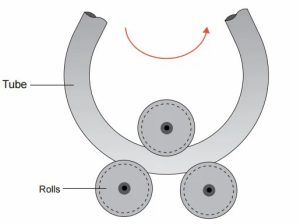

| Top bend | Rolling |

|

|

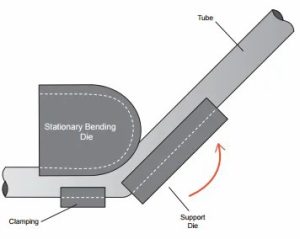

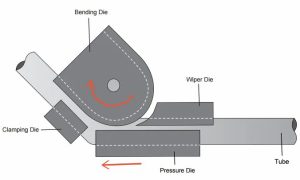

| Bending | Pull-type bending pipe |

|

|

| Pull-type tube bending with rear-side assist | Free Radius Bends |

|

|

Precautions for using pipe bending machine:

1. Electrical control boxes, hydraulic valves, motors and other electrical appliances must be kept clean and dry, and must not be exposed to water. Check the wire jackets of the above components frequently to ensure that they are not damaged to prevent leakage.

2. When moving the machine, there should be no major bumps, and the components of the machine should not be hit at will.

3. The oxide scale that falls off the power roller should be cleaned in time.

4. The transmission bearing parts should be regularly maintained and lubricated.

5. The auxiliary rolling workbench must be kept level with the main machine roller.

6. The reversing handle should not be pulled or pushed violently.

Daily maintenance and maintenance items of pipe bending machine:

1. After the new machine has been running for 50 hours, check and tighten the bolts to see if they are loose.

2. After the new machine has been running for 100 hours (about 15 days), replace the hydraulic oil.

3. After the new machine has been running for 200 hours, replace the reducer oil.

4. Replace the hydraulic oil and reducer oil once a year.

5. Fill the pressure shaft with butter every shift.

This article introduces the basic knowledge of using pipe bending machines. If you need to know more or have product needs for a pipe bending machine, please contact us bender@antishicnc.com and a professional will answer your questions.

More previous articles:

What is the push – bending function of CNC pipe benders?

Application of CNC pipe bending machines in the automotive industry

Key words: Pipe bending machine, Pipe bender, tube bender, Pipe cutting machine

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.