One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

In the field of pipe processing, the push – bending function of pipe benders is leveraging its unique advantages and emerging as a crucial technology for numerous industries to achieve efficient and precise pipe processing. So, what exactly is the push – bending function of pipe benders? The answer is right below.

|

|

Working Principle

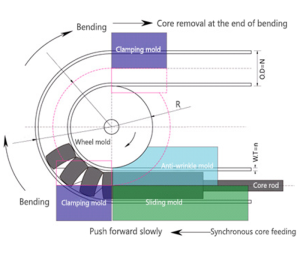

The push – bending function primarily relies on the pushing device of the pipe bender to apply thrust to the pipes. One end of the pipe is fixed, and the other end moves along pre – designed bending molds (such as bending dies and guiding dies) under the action of the thrust. During the pushing process, the pipe undergoes plastic deformation and gradually bends into the desired shape and angle. For example, hydraulic pipe benders generate a powerful thrust through the hydraulic system to push the pipes to complete the bending on the molds. This method can provide stable and substantial thrust, making it suitable for the push – bending processing of pipes of various materials and specifications.

Features

Capable of processing large – diameter pipes: It can handle pipes with large diameters. For the bending of large – caliber pipes, the push – bending function has obvious advantages. During the push – bending process, the force exerted on the pipe is relatively uniform, which allows for better control of the deformation of large – diameter pipes during bending and avoids problems such as excessive deformation or damage.

High bending accuracy:With the constraint and positioning of the mold, push – bending can precisely control the bending radius and angle of the pipe. Both the dimensional accuracy and shape accuracy of the bent part can be well guaranteed. Meanwhile, the pipe has good roundness after bending and high surface quality, which can effectively reduce defects such as wrinkles and cracks, meeting the requirements of high – precision processing.

High production efficiency: For the mass production of elbow pipes of the same specification, the push – bending operation is relatively simple and fast. Once the parameters of the pipe bender and the mold are adjusted, the pipe bending process can be carried out continuously, enabling a large number of elbow pipe production tasks to be completed in a relatively short period of time and improving production efficiency.

Scope of application

Industrial pipeline manufacturing: In the construction of pipeline systems in industries such as petroleum, chemical, and natural gas, a large number of elbow pipes with different specifications and angles are required to connect various pipeline components. The push – bending function can produce elbow pipes that meet various working conditions, ensuring the sealing and stability of the pipeline system. For example, in the pipeline installation of petrochemical plants, push – bending pipe benders can be used to process elbow pipes made of carbon steel, stainless steel, etc., with different diameters and wall thicknesses.

Building and decoration fields: In construction projects, it is used for the bending of pipes in air – conditioning systems, water supply and drainage systems, as well as the bending and shaping of some decorative metal pipes. The push – bending function can produce beautiful and high – precision elbow pipes to meet the requirements of construction and decoration. For instance, in the installation of air – conditioning ventilation pipes in some high – end office buildings, aluminum alloy elbow pipes processed by push – bending are used, which not only ensures the ventilation effect but also has a good appearance.

Mechanical manufacturing industry: In the manufacturing process of mechanical equipment, elbow pipes of various shapes are required as components, such as oil pipes in hydraulic systems and automobile exhaust pipes. The push – bending function can produce high – precision elbow pipes according to design requirements, ensuring the performance and quality of these components. For example, in automobile manufacturing, push – bending pipe benders can be used to process stainless – steel exhaust pipe elbow pipes of different shapes and sizes to meet the exhaust requirements of automobile engines and the overall appearance design requirements of the vehicle.

Shanghai ANTISHICNC Oil – electric Hybrid Servo Pipe Bender CNC6503RES

The CNC6503RES combines the advantages of hydraulic technology and servo motors, achieving higher accuracy, faster speed, and lower energy consumption.

Main technical parameters of CNC6503RES

| Parameter | UNIT | CNC6503RES |

| Max bending capacity/carbon steel | mm | 63.5*2.0 |

| Max bending capacity/stainless steel | mm | 58*1.5 |

| Max bending capacity/metal square tube | mm | 45*3.0 |

| Bending radius range/round tube | mm | 25-250 |

| Bending radius range/square tube | mm | 25-200 |

| Minimum coil radius | mm | ≥7D |

| Max pipe diameter for reciprocating feeding | mm | 40 |

| Bending angle range | Degree | 190 |

| Max effective core penetration distance | mm | 3000 |

| Machine working height | mm | 1200 |

| Adjustable stroke of mold | mm | 20-250 |

| Bend pipe servo motor | KW | 11 |

| bending speed | Deg/sec | 100 |

| Bending accuracy | Degree | ±0.05 |

| Feeding servo motor | KW | 5 |

| Feeding speed | Mm/sec | 450-750 |

| Feeding accuracy | mm | ±0.01 |

| Rotary tube servo motor | KW | 0.75 |

| Tube speed | Deg/sec | 98 |

| Tube rotation accuracy | Degree | ±0.01 |

| Auxiliary thrust movement speed | Mm/sec | 100 |

| Core threading speed | Mm/sec | 80 |

| hydraulic motor | KW | 7.5 |

| system Max pressure | Kgf/cm2 | 140 |

| Preset pressure | Kgf/cm2 | 100 |

| total power | KW | 30.5 |

| Machine length | Mm | ≈5200 |

| Machine width | Mm | ≈1250 |

| Machine height | Mm | ≈1400 |

| Machine weight | KG | ≈3000 |

If you have the need to process pipes with complex shapes and high precision requirements, welcome to consult Shanghai ANTISHICNC. We have rich experience in manufacturing and and application of CNC pipe bending machine, and can provide you with professional technical support.

Learn More:

Wire Bending Machine User Guide

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.