One-stop Bending Solutions For Wires, Tubes And Pipes

One-stop Bending Solutions For Wires, Tubes And Pipes

Recently, Shanghai ANTS Machiner Equipment Co., Ltd. successfully received a table and chair processing manufacturer from Saudi Arabia. CNC pipe bending machines are needed to process table and chair products. It mainly focuses on several aspects: the manufacturing of table and chair frames, customized production can also be provided, which also reduces costs, reduces labor and improves efficiency.

CNC pipe bending machines improve production efficiency and product quality in the table and chair industry through efficient and precise processing, while supporting customization and innovative design, reducing production costs and promoting industry development.

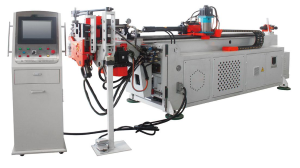

According to the customer’s drawings, a fully automatic CNC pipe bending machine – CNCDW38CNC-3A-1S was matched. This is a hybrid servo pipe bending machine that conforms to the principles of dynamic mechanics, has a high rigidity mechanical structure design and precision process level. While maintaining structural strength, the simple bending hand and bending head design provide the largest bending space, minimizing the machine interference range.

The following are the basic parameters of CNCDW38CNC-3A-1S CNC pipe bending machine:

| Basic parameters | Unit | CNC3804RET |

| Maximum bending capacity/carbon steel | mm | 38*2.0 |

| Maximum bending capacity/stainless steel | mm | 32*2.0 |

| Maximum bending capacity/metal square tube | mm | 30*2.0 |

| Bending radius range/round tube | mm | 30-200 |

| Bending radius range/square tube | mm | 40-180 |

| Maximum tube rolling capacity | mm | 35*2.0 |

Next, the engineers of ANTISHICNC will introduce you in detail the general process of the price of tables and chairs with the fully automatic CNC pipe bending machine:

1.Preparation

Design drawings: Prepare the design drawings of tables and chairs, and clarify the bending angle, size and shape of the pipes.

Select materials: Select suitable metal pipes (such as stainless steel, aluminum alloy, etc.) according to the needs.

Inspect equipment: Make sure that the CNC pipe bending machine is in normal condition and the molds and tools are installed correctly.

2.Programming and setup

Input data: Input the bending parameters in the design drawing into the CNC system.

Select mold: Select the appropriate mold according to the pipe diameter and bending radius.

Calibrate equipment: Calibrate the CNC pipe bending machine to ensure accuracy.

3.Clamping the pipe

Fixing the pipe: Clamp the pipe correctly on the pipe bending machine to ensure stability.

Adjusting the position: Adjust the starting position of the pipe according to the programming data.

4.Bending process

Starting the equipment: Start the CNC pipe bending machine to automatically complete the bending.

Monitoring process: Monitor the processing process in real time to ensure that it is correct.

5.Quality inspection

Dimension inspection: After processing, check whether the size and angle meet the requirements.

Appearance inspection: Check whether the surface is damaged or defective.

6.Subsequent processing

Cutting and welding: Cut or weld the pipe as needed.

Surface treatment: Perform painting, polishing and other treatments to improve appearance and durability.

7.Assembly and packaging

Assembling tables and chairs: Assemble the processed pipes and other components into tables and chairs.

Packaging: Pack and prepare for shipment.

If you have any questions, please contact Shanghai ANTISHI Machiner Equipment Co., Ltd. through our website information. Engineers will match you with efficient machine tools and professional services.

Learn More:

Wire Bending Machine User Guide

Our equipment has CE, ISO quality inspection certificate, so the quality is guaranteed to be cost-effective. According to different processing requirements, machines can be customized to fit for your usage, to provide customized services. In the processing period, we strictly control the production process, to ensure the quality of clearance, standardize the process, strict implementation.